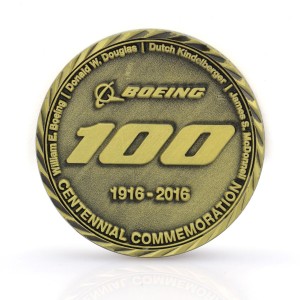

Idizayini Yekhwalithi Enhle Yenze Eyakho Ibe Isindayo Ngebhokisi Legolide Elinakiwe Uhlamvu Lwesiliva Lwesiliva Olwenzelwe Wena Isikhumbuzo Sezinhlamvu zemali Zasendulo

Imininingwane Yomkhiqizo

Izinhlamvu zemali zobufakazi

(Izinhlamvu zemali zegolide zobufakazi (umphumela wesibuko uhlamvu lwegolide).

Ubufakazi Sliver Coins

(Izinhlamvu zemali zegolide zobufakazi (umphumela wesibuko uhlamvu lwegolide).

Isingeniso senqubo yokukhiqiza yezinhlamvu zemali eziyisikhumbuzo

Indiza engezansi yalolu hlamvu lwesikhumbuzo lwegolide nesiliva (isahluko) kufanele ibe isicaba kakhulu futhi ikhanye njengesibuko, ukuze umehluko phakathi kwephethini yayo nendawo engaphansi kuqine kakhulu futhi isigaba sihluke kakhulu. Ikakhulukazi ngokusebenzisa ukufakela, ukuphrinta nokusika ukufa; Ithuluzi litholakala ngokuqeda, ukucwenga, ukuphrinta nokusika, bese kuba imaski, ukupholisha nezinye izindlela.

Inqubo Yezandla

Uhlelo lokuphatha nokugeleza kokukhiqiza.

Sinolwazi oluthuthukisiwe lokuphatha, ukugeleza kokukhiqiza kanye nokulawula ikhwalithi izindlela zokuhlinzeka amakhasimende ngemikhiqizo eqinisekisiwe yekhwalithi ephezulu.

Idizayini Yobuciko Nobufakazi Bobuciko. ubufakazi bedijithali buyakhiwa futhi busetshenziselwa ukugunyazwa kwamakhasimende kanye nokubhekisela kuyo yonke inqubo yokukhiqiza.

Ukugxiviza

Ibumba indawo yensimbi ukwenza umklamo. I-CNC machining isetshenziselwa ukuqopha umklamo wakho endaweni yesikhunta.

Imibala ehlukahlukene yokucwenga manje ingacutshungulwa.

I-Zinc Alloy Die Casting * Umjovo : Izinto ezifakwa esikhunjini. * Ukuqedwa: Lapho kuqedwa umjovo, udoti uyasuswa ukuze kuvezwe umklamo oqediwe.

Ukuhlanganisa nokupakishwa

Mayelana NATHI

Izigaba zemikhiqizo

-

Ucingo

-

I-imeyili

-

Whatsapp

whatsapp

-

I-WeChat

I-WeChat